Third Party Revert Storage Warehouse

A mixture of solids, turnings, powders are free issued for consolidation and refining

Third Party Revert Storage Warehouse

A mixture of solids, turnings, powders are free issue for consolidation and refining

Third Party Bulk Material Receipt & Yard Storage

Goodwin employs site material segregation to facilitate the processing of iron, nickel and cobalt base materials

Material Charges Raised To Customer Blend Requirements

Goodwin conducts primary melting through large scale electric arc and induction furnaces

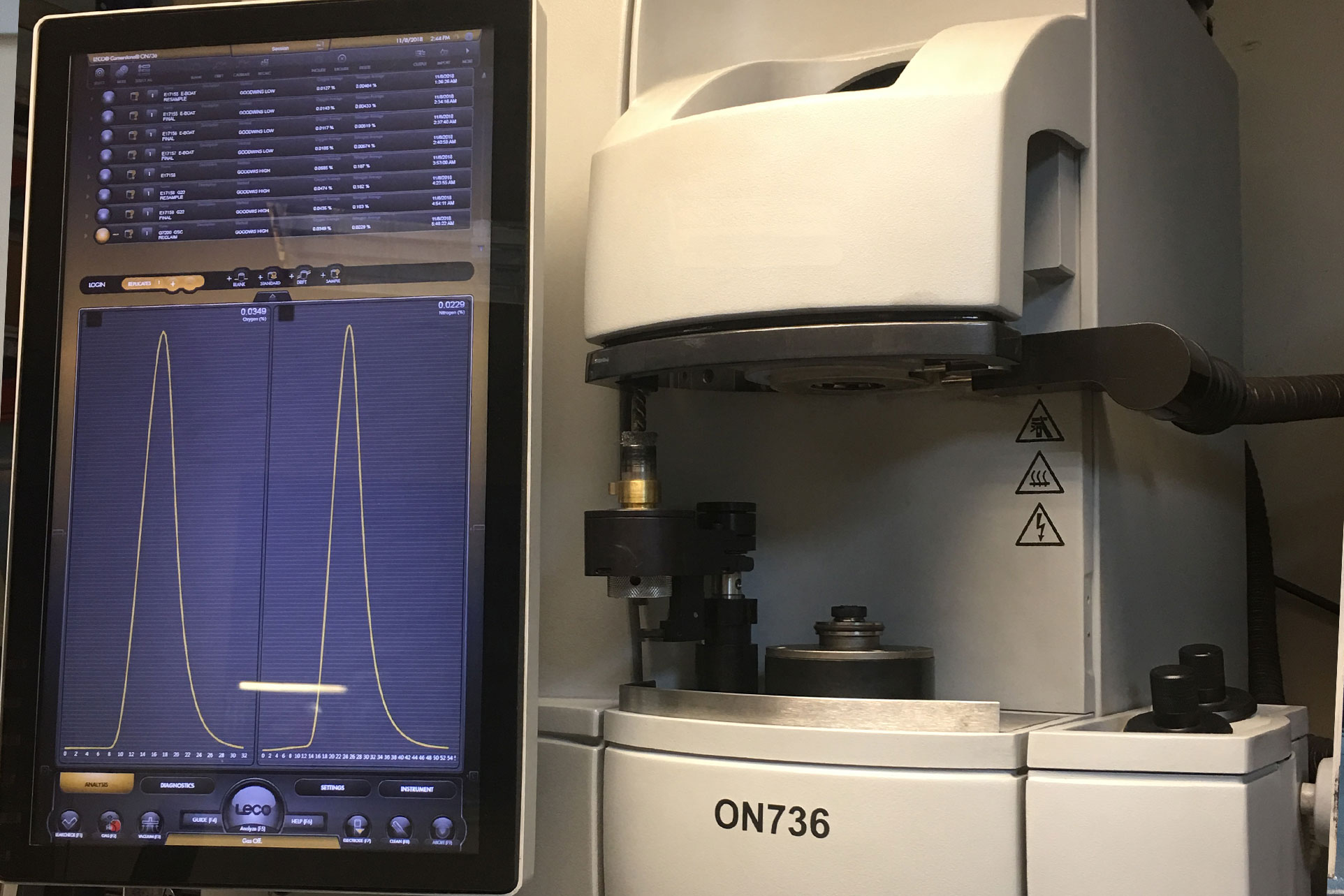

In Process Chemical Laboratory with Combustion & Spectrographic Analysis

Goodwin maintains the capability to analyse oxygen, hydrogen and nitrogen as part of the refining process

Melt Shop Feed Stock - 1000Kg Cast Billets

Goodwin produces cast billets and pig ingots of know analysis which offer melt shops master alloys to melt

Refined Third Party Material Prior To Despatch

Quarantine material prior to despatch pending certificate of known analysis and product weight